|

|

|

|

| |

|

|

|

|

| |

|

|

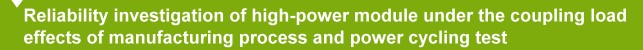

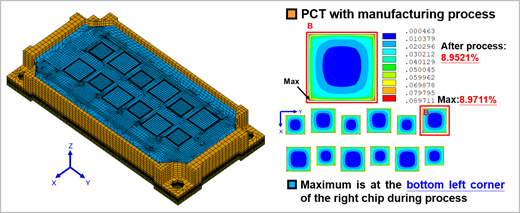

Personal vehicles have shifted from fuel to

hybrid/electric power in pursuit of reduced

carbon emission due to the increasing awareness

of environmental protection. Power modules have

become a crucial component of modern-day

electric vehicles (EVs) considering the

increasing demand for high power and voltage

output. However, the direct bonded copper

substrate in the traditional power module still

has warpage issues after the manufacturing

process. This phenomenon leads to poor heat

dissipation after assembly with heat sink due to

high switching speed with large heat generation

rates within the components, which eventually

fails to meet the requirements of modern-day

EVs. Additionally, mechanical and thermal issues

will affect the reliability of power modules.

Therefore, establishing a process-oriented

simulation methodology, which considered the

coupling effect of thermal and electrical

responses to improve the mechanical behavior,

and optimizing the reliability of the IGBT

high-power module, are crucial topics in the

current research. |

|

|

|

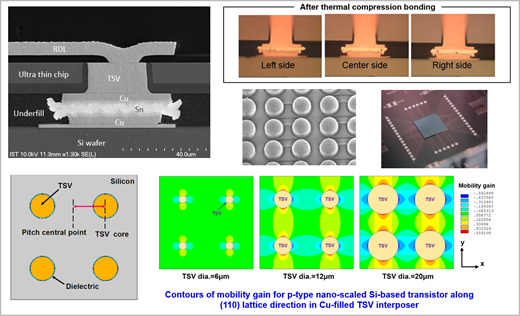

Fig.1 Fabrication, wafer level assembly,

simulated analysis of ultra thin chip of 3D ICs. |

|

|

|

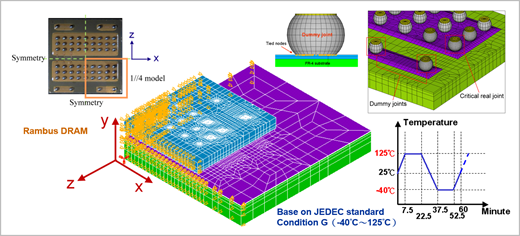

Fig.2 Finite element model and

simulation of advanced packaging architecture. |

| |

|

|

|

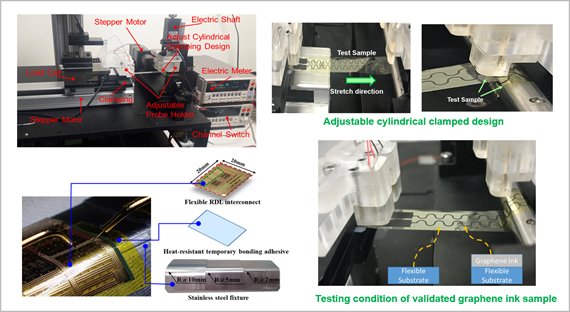

Packaging technology has gradually developed

toward minimized dimension, high I/O count, and

multi-chip integrated architecture. Fan-out

panel-level packaging (FOPLP) has currently

become the most popular packaging technology

because it has the highest potential to overcome

the previously mentioned difficulties. However,

several concerned mechanical characteristics,

such as the coefficient of thermal extension

mismatch induced from heterogeneous integration

and heat and chemical reactions of the molding

compound, would result in serious warpage issues

during the manufacturing process of FOPLP. Such

issues would eventually lead to packaging

reliability deterioration. Thus, the macroscopic

and microscopic physical behaviors of material

models used in the simulated analysis should be

carefully considered to resolve the significant

dimension mismatch within the components of

actual FOPLP vehicles. Investigations on

advanced packaging techniques based on the

summary of the aforementioned challenges would

be the next considerable leap among the research

topic of mechanical engineering. |

|

|

|

Fig.3 Power module with insulated metal

substrate (IMS). |

|

|

|

Fig.4 Finite element model & equivalent

plastic strain distribution of IMS module under

PCT. |

| |

|

|

|

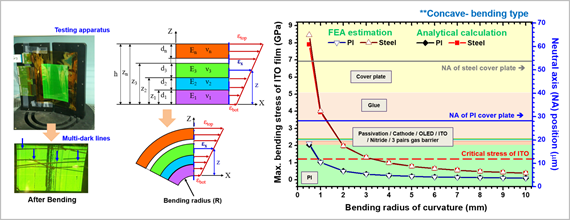

Along with the innovated film materials,

flexible electronics has rapidly grown among

wearable devices with the advantages of light

weight, minimized thickness, and applicability

on various shapes and sizes. The specific

feature of flexible and foldable electronics

lies in the capability to withstand repeated

loadings under a few millimeters of bending

radius. The soft device has various

applications, such as wearable device, curved

display, flexible solar cell, and printed

electronics. Additionally, the most crucial part

of flexible display includes flexible glass,

metal foils, and polymer films. Particularly,

flexible glass has outstanding optical

applications and low thermal extension

coefficient and could be adopted as a barrier to

prevent vapor and air from entering the package.

However, flexible glass also has the

disadvantages of fragility, increased production

cost, and high restrictions on applied bending

radius. Therefore, the locations of multiple

neutral axes should be seriously considered to

prevent the flexible glass from fracture. The

number and positions of the neutral axes can be

appropriately configured with the mechanical

model and analytic results presented in this

research. This configuration is expected to be

an important design reference for the

next-generation soft electronic architectures. |

|

|

|

Fig.5 Actual measurement platform

utilized in the mechanical loading tests of

flexible hybrid electronics (FHE). |

|

|

|

Fig.6 The screen of OLED flexible

display appears multi-dark lines induced by

testing apparatus with thousands bending

performance. Also, strain distribution of

flexible display is derived based on the

schematic drawing. |

| |

|

|

|

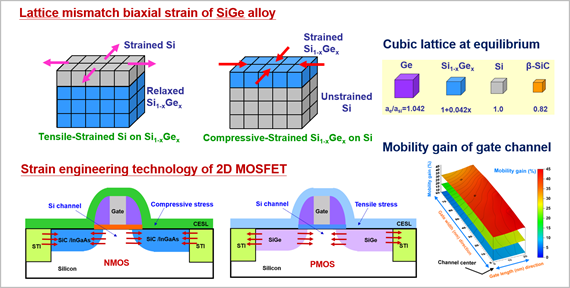

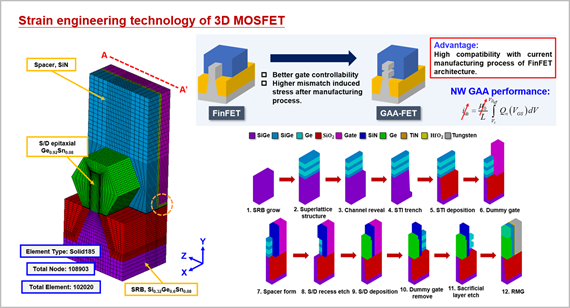

The

dimension of semiconductors has shifted from

micron to nanometer scale due to the rising

demand for high performance on electronic

devices. However, the conventional method of

shrinking the device by decreasing the

characteristic dimension (length and width) of

the actual device has led to some bottlenecks in

manufacturing. An alternative way is to utilize

the advantages of 3D structures, including

FinFET and gate-all-around FET, to improve the

controllability and performance of the

semiconductor device. Additionally,

process-induced performance enhancements, such

as gate-last, high-k metal gate novel

semiconducting materials (SiGe, Ge, and III-V),

and strain engineering, can boost the overall

performance of the device. In the evolution of

semiconductor architecture, the technology node

is used as a description of the generation for

the semiconductor device, while the 22 nm

technology node was regarded as the final

chapter of the planar device. Novel techniques

in 7 nm FinFET and 3 nm GAA-FET have been

observed to be candidates due to improved

electrical performance. Thus, the possibility of

strain engineering to obtain further boost is

regarded as a novel topic in the semiconductor

industry. |

|

|

|

Fig.7 Mechanism of induced lattice

mismatch stress within 2D MOSFETs and the

schematic diagrams of preferred stress

components in N/P MOSFETs. |

|

|

|

Fig.8 Process-oriented device simulation

considered in advanced 3D MOSFETS. |

| |

|

|

|

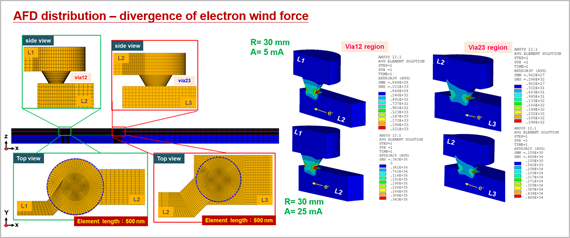

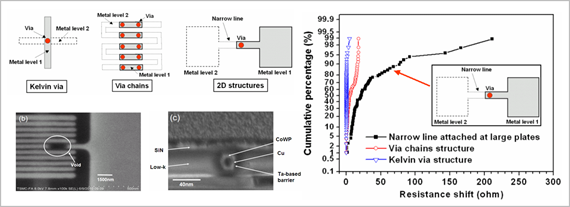

For the next generation of integrated circuits,

the copper/low-k interconnect system has the

advantage of reducing RC delay between adjacent

lines and connections, thereby minimizing the

energy consumption. Therefore, this system is

regarded as the best solution to interconnect

materials for current advanced chips. Along with

the decreasing dimension from micron to

nanometer scale, the emerging difficulties in

reliability and failure mechanisms with the

reduction of interconnection width and the

geometry variation in the circuit must be

urgently studied. The major issues of

electromigration (EM) will lead to void growth

inside the copper line. Moreover, the

interconnect comprising different materials

suffers from a mismatch considering the thermal

expansion coefficient, which drives the vacancy

from grain boundaries to via area due to stress

gradient. This phenomenon eventually causes

component failure, which is also known as the

stress migration (SM) effect. By contrast,

reliability problems regarding interfacial

fractures in bonded interfaces between low-k

materials and barrier layers should be carefully

considered with the application of external load

or process-induced stress. Therefore, the

current research focuses on the reliability

physics and failure mechanism as well as the

impacts of scaling sizes and geometry variations

for interconnects. Moreover, the next-generation

interconnect system, including novel processes

and new materials, will be comprehensively

explored and discussed. |

|

|

|

Fig.9 Simulation investigation of

nano-scaled interconnect reliability by using

Atomic Flux Divergence (AFD) based approach. |

|

|

|

Fig.10 A new stress migration failure

mode in highly scaled Cu/Low-k interconnects. |

|

|

| |

|

|

|

|

| |

|

|

|